Did you know that:

Electric car sales – including battery electric vehicles (BEVs) and plug-in hybrid electric vehicles (PHEVs) – up 55% from 2021.

Over just five years, from 2017 to 2022, EV sales jumped from around 1 million to more than 10 million.

A report by the International Energy Agency (IEA) predicts that 145 million electric cars will be on the road by 2030 and that electric car sales will overtake gasoline and diesel cars by 2040.

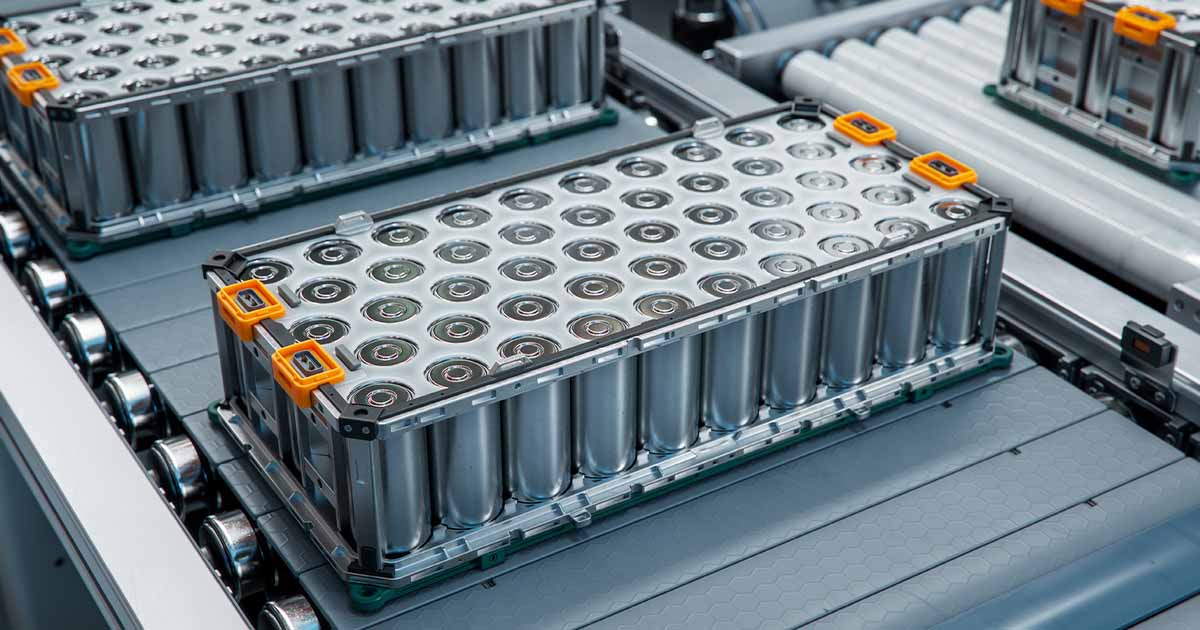

In recent years, the electric vehicle (EV) industry has experienced remarkable growth and transformation. Electric vehicles are a trending component of our sustainable future. As the demand for EVs continues to rise, so does the significance of efficient and environmentally friendly battery manufacturing.

Flooring may not be the first thing that comes to mind in the context of manufacturing, but it ensures the smooth operation and overall productivity of EV battery plants.

In today’s blog post, we will look at the challenges faced by battery production facilities and the advantages of using concrete flooring solutions.

At BNE, we are trusted experts in concrete finishing. For the past 30 years we have gained the knowledge, equipment, and skills to properly install concrete for any type of project. We use industry-leading technology and expertise to provide the client with a concrete structure that will last. Our clients, mainly large-scale players in Ontario in the Food & Beverage, Automotive, Tire, Cannabis and Beer industries, seek us out because we are a single source providing concrete finishing, polish and epoxy. This saves them time, money, and the hassle of communicating their needs to various contractors.

Do not hesitate to reach out to us for your next construction project. We are just one phone call or email away!

The Significance of EV Battery Manufacturing

The importance of manufacturing electric vehicle (EV) batteries is at the forefront of the world's shift towards more eco-friendly transportation. This can be seen in the rapid expansion of the electric vehicle industry.

As consumers and governments increasingly prioritize eco-friendly alternatives to traditional vehicles, the demand for electric cars has surged. To support this growth and address environmental concerns, companies have created efficient and sustainable manufacturing processes that not only meet the rising production requirements but also minimize the ecological footprint of EV battery production.

Ultimately, the production of electric vehicle batteries not only contributes to a cleaner environment but also offers economic benefits by fostering innovation, creating job opportunities, and driving technological advancements in the clean energy sector.

Challenges in Battery Production Facilities

Battery production facilities face several challenges, mostly due to the surging demand for electric vehicle batteries. They must meet high production requirements while ensuring safety and environmental compliance, which is a complex balancing act in the highly specialized and high-tech environment of battery manufacturing plants.

Electric vehicle plants differ significantly from traditional automotive plants, as they demand climate-controlled clean rooms where each room must maintain specific humidity, heat, and cooling levels, emphasizing the critical importance of selecting the right flooring for each distinct area.

High-Demand Production Requirements

The electric vehicle market is experiencing rapid growth, leading to an unprecedented demand for EV batteries. Battery production facilities must meet high production targets to keep pace with the surging demand. This demand places immense pressure on production lines, equipment, and resources, which demands efficient and optimized processes.

Safety and Operational Efficiency

Battery manufacturing involves handling chemicals, high-energy materials, and intricate processes, making safety a massive concern. Operational efficiency and worker welfare are crucial to maintaining productivity and ensuring a safe working environment.

The Role of Flooring in Addressing These Challenges

The right flooring can address the challenges of battery production facilities, as it provides the foundation for safe and efficient operations. Durable and well-designed flooring can withstand heavy machinery, corrosive chemicals, and high-traffic areas, contributing to safety and productivity.

Properly designed flooring solutions can also help manage environmental concerns by facilitating easier cleanup, waste containment, and sustainable practices within the facility.

Concrete Flooring Solutions

Concrete flooring solutions offer a range of benefits that make them a practical choice for battery production facilities, ensuring safety, longevity, and efficiency in the manufacturing process.

Advantages Of Concrete Flooring for Battery Manufacturing

Excellent load-bearing capacity: Concrete floors can support heavy battery manufacturing equipment and materials without cracking or deteriorating.

Chemical resistance: Concrete is resistant to corrosive chemicals often used in battery production, ensuring the longevity of the flooring.

Low-maintenance: Concrete floors are easy to clean and maintain, reducing downtime and operational costs.

Temperature stability: Concrete floors provide thermal stability, which is very important for battery production processes.

Types Of Concrete Flooring Systems

Concrete floors are known for their exceptional durability, with a lifespan that can extend for decades. They are resistant to wear and tear, making them an ideal choice for high-traffic areas and heavy machinery. Properly maintained concrete floors can withstand the rigors of battery manufacturing, providing long-term value and cost savings for facility owners.

Polished Concrete

Polished concrete is a popular choice due to its high-gloss finish and durability. It enhances the aesthetics of the facility while providing a smooth and easy-to-clean surface.

Epoxy Coatings

Epoxy coatings are applied over concrete to create a seamless, chemical-resistant surface. They come in various colors and can include non-slip additives for safety.

High-Performance Concrete

High-performance concrete is engineered for specific requirements, such as extreme durability, resistance to heavy loads, or temperature control. It can be customized to suit the unique needs of battery manufacturing facilities.

Cost-Efficient and Durable Flooring Options

Concrete flooring is a remarkably cost-efficient option for EV battery manufacturing facilities. Its durability means that the flooring can withstand the heavy demands of industrial use without the need for frequent replacements or extensive maintenance. This durability translates into significant cost savings over time.

Energy-efficient flooring solutions can also incorporate radiant heating systems that help regulate indoor temperatures, reducing the need for additional heating or cooling.

Health and Safety with Concrete Flooring

Concrete flooring not only offers structural advantages but also helps minimize the health and safety risks of battery manufacturing facilities by providing an optimal workspace, reducing the need to use harmful chemicals, and contributing to healthier indoor air quality.

Stability and Support

Concrete floors can be treated with non-slip finishes, reducing the risk of workplace accidents. This is particularly crucial in environments where spills and high-traffic areas are common. The solid and stable nature of concrete flooring provides a secure platform for heavy machinery and equipment, further ensuring the safety of workers operating in these environments.

Lower Maintenance and Cleaning Requirements

Concrete floors require less maintenance and fewer cleaning chemicals compared to other flooring materials, reducing the use of harmful cleaning agents and their associated environmental impact. The reduced need for frequent maintenance also results in lower energy and resource consumption.

Improved Indoor Air Quality

Unlike some flooring materials that can trap allergens and pollutants, concrete does not emit harmful VOCs (Volatile Organic Compounds) into the indoor environment. This contributes to healthier indoor air quality, benefiting both workers and the environment by reducing the need for air-purifying systems and their energy consumption.

At BNE, we are trusted experts in concrete finishing. We have the knowledge, equipment, and skills to properly install concrete for any type of project. We use industry-leading technology and expertise to provide the client with a concrete structure that will last. Our clients seek us out because we are a single source providing concrete finishing, polish and epoxy. This saves them time, money, and the hassle of communicating their needs to various contractors.

Do not hesitate to reach out to us for your next construction project. We are just one phone call or email away!